IQ/OQ/PQ qualification ensures equipment is properly installed, operates correctly, and performs as intended, crucial for regulatory compliance and product quality in pharmaceutical and related industries through structured validation processes.

Overview of IQ/OQ/PQ in Equipment Validation

IQ/OQ/PQ are critical phases in equipment validation, ensuring systems are installed, operate, and perform as intended. IQ confirms proper installation according to manufacturer specifications, while OQ verifies operational consistency under defined conditions. PQ assesses performance over time, ensuring reliability and consistency. These stages involve rigorous testing, documentation, and adherence to protocols to guarantee compliance with regulatory standards. Proper execution of IQ/OQ/PQ ensures equipment functionality, data integrity, and product quality, minimizing risks and deviations. Each phase builds on the previous one, providing a structured approach to validation. Examples include protocols for laboratory equipment, manufacturing systems, and software, ensuring traceability and GMP compliance throughout the lifecycle of equipment validation activities.

Importance of IQ/OQ/PQ in Regulatory Compliance

IQ/OQ/PQ are essential for ensuring regulatory compliance, as they verify that equipment operates within specified parameters, producing consistent and high-quality output. These processes align with FDA and GMP requirements, ensuring data integrity and traceability. Proper documentation and approval of protocols prevent deviations and facilitate audits. Compliance is maintained through calibrated instruments, trained personnel, and controlled environments. Examples from pharmaceutical and biotech industries demonstrate how IQ/OQ/PQ protocols ensure adherence to standards, minimizing risks and ensuring product safety. Regulatory bodies emphasize these validations to confirm equipment reliability, making them critical for maintaining compliance and avoiding non-conformities in highly regulated environments.

Installation Qualification (IQ)

IQ verifies equipment installation meets manufacturer and regulatory specifications, ensuring proper setup and functionality. It involves checking documentation, hardware, and software alignment, with examples in pharmaceutical validation.

Definition and Purpose of IQ

Installation Qualification (IQ) is the first phase of equipment validation, ensuring that equipment is delivered, installed, and configured correctly according to manufacturer specifications and regulatory requirements. Its primary purpose is to verify that all components, hardware, and software are properly set up and functional in the intended environment. IQ lays the foundation for subsequent qualification stages by confirming that the equipment meets design and operational criteria. It ensures compliance with Good Manufacturing Practices (GMP) and regulatory standards, providing documented evidence of proper installation. This step is critical for ensuring equipment performance, safety, and reliability, ultimately supporting the production of quality products.

Key Activities in IQ

Key activities in Installation Qualification (IQ) involve verifying that equipment is delivered, installed, and configured correctly. This includes checking manufacturer specifications, reviewing supplier documentation, and ensuring all components are present. Activities also encompass verifying software installation, performing physical inspections, and confirming wiring and piping connections. Additionally, IQ involves checking safety features, power requirements, and environmental conditions. A detailed checklist is used to ensure all steps are completed. Documentation includes serial numbers, model numbers, and installation dates. These activities ensure the equipment is ready for operational testing, aligning with regulatory requirements and manufacturer guidelines. Proper execution of IQ activities is essential for a smooth transition to Operational Qualification (OQ).

Examples of IQ Documentation

Examples of IQ documentation include equipment inventory lists, installation checklists, and supplier-provided documentation. These documents verify that equipment is delivered, installed, and configured correctly. IQ records often include serial numbers, model numbers, and installation dates. Acceptance test reports and factory acceptance test (FAT) certificates are also common. Documentation may include photographs of installations, wiring diagrams, and configuration settings. Additionally, calibration certificates for instruments and tools used during installation are typically included. These documents ensure compliance with manufacturer specifications and regulatory requirements. Properly maintained IQ documentation serves as a foundation for subsequent qualification stages, such as OQ and PQ, ensuring traceability and accountability throughout the validation process.

Operational Qualification (OQ)

OQ verifies equipment functionality under operational conditions, ensuring it performs as intended. It bridges IQ and PQ, confirming systems operate correctly according to SOPs and specifications.

Definition and Purpose of OQ

Operational Qualification (OQ) is the process of verifying that equipment operates consistently and effectively under normal operating conditions. Its primary purpose is to ensure that the equipment performs as intended by the manufacturer and meets specified requirements. During OQ, tests are conducted to evaluate the equipment’s functionality, safety features, and performance limits. This step bridges the gap between Installation Qualification (IQ) and Performance Qualification (PQ), confirming that the system is ready for routine operation. OQ is crucial for regulatory compliance, providing documented evidence of equipment reliability and consistency. It involves pre-test checks, test procedures, and post-test actions, ensuring all operational parameters are within acceptable limits before proceeding to PQ.

Key Activities in OQ

Key activities in Operational Qualification (OQ) involve verifying that equipment operates consistently under normal and worst-case conditions. This includes testing all functional and operational aspects, such as temperature, pressure, and flow rates. Alarm systems and safety features are also evaluated to ensure they function as intended. Performance testing is conducted using approved protocols to confirm the equipment meets specified criteria. Additionally, OQ involves verifying user interfaces, data collection systems, and communication between interconnected devices. All activities are documented, and deviations are addressed to ensure compliance. Finally, OQ ensures that operators are trained on equipment operation and maintenance, preparing the system for routine use in production environments.

Examples of OQ Documentation

Examples of Operational Qualification (OQ) documentation include detailed test reports, operational checklists, and verification records. These documents verify that equipment functions as intended under normal and worst-case conditions. Test reports outline results of functional tests, such as temperature, pressure, and flow rate validations. Operational checklists ensure all system features, like alarms and controls, are tested and approved. Verification records confirm that equipment meets specified performance criteria. Additionally, OQ documentation may include calibration certificates, operator training records, and maintenance schedules. These documents are essential for regulatory compliance and serve as evidence that the equipment is ready for production use. Proper archiving ensures traceability and audits.

Performance Qualification (PQ)

Performance Qualification (PQ) verifies equipment performance under routine conditions. Examples include performance reports, trend analysis, and final qualification reports, ensuring consistent operation and compliance with specifications.

Definition and Purpose of PQ

Performance Qualification (PQ) is the final stage of equipment validation, ensuring that the system operates consistently and effectively under routine conditions. Its purpose is to confirm that the equipment performs as intended over time, meeting specified requirements and producing reliable results. PQ involves testing the equipment under actual operating conditions, simulating real-world scenarios, and verifying consistency across multiple runs; This step is critical for regulatory compliance, as it demonstrates that the system is suitable for its intended use. Examples include operational checks, performance testing, and long-term monitoring. Successful PQ ensures that the equipment is fully validated and ready for production or operational use.

Key Activities in PQ

Performance Qualification (PQ) involves verifying equipment performance under routine operating conditions. Key activities include reviewing design and operational parameters, conducting performance tests, and ensuring consistency across multiple runs. Testing is done under actual operating conditions to simulate real-world use. Data collection and analysis are critical to confirm that the system meets specified requirements. Additionally, PQ includes verification of control systems, alarm functionality, and long-term stability. Documentation of all test results is essential for compliance. These activities ensure the equipment operates reliably and consistently, producing accurate and reproducible results. PQ is the final step before the equipment is deemed fully validated and ready for operational use.

Examples of PQ Documentation

Performance Qualification (PQ) documentation typically includes detailed test protocols, raw data sheets, and summary reports. These documents validate that the equipment performs consistently under routine conditions. Examples include test protocols outlining the procedures, expected results, and acceptance criteria. Raw data sheets capture actual test measurements, while summary reports compile and analyze the findings. Additional documentation may include deviation reports if any discrepancies arise, along with corrective actions taken. These records ensure transparency, traceability, and compliance with regulatory standards. Properly maintained PQ documentation serves as evidence of a system’s reliability and readiness for operational use. It is essential for audits and demonstrating adherence to GMP and other regulatory requirements.

IQ/OQ/PQ Protocols

IQ/OQ/PQ protocols are structured documents outlining procedures for validating equipment. They often include test scripts, acceptance criteria, and forms for data recording and approvals. Many are available as downloadable PDF templates online, providing a customizable framework for ensuring compliance with regulatory standards during equipment validation processes across industries.

Overview of IQ/OQ/PQ Protocol Structure

An IQ/OQ/PQ protocol structure typically includes sections like scope, objectives, responsibilities, test procedures, acceptance criteria, and documentation requirements. It provides a clear framework for validating equipment, ensuring compliance with regulatory standards. The protocol outlines step-by-step activities, from installation to performance testing, with predefined acceptance limits. Templates for IQ/OQ/PQ protocols are widely available, often in PDF format, offering customizable solutions for various industries. These templates guide users through the validation process, ensuring consistency and thoroughness. Properly structured protocols help minimize errors and deviations, providing a systematic approach to equipment qualification. Examples of such protocols can be found in regulatory guidelines and industry resources, serving as valuable references for organizations.

Key Components of a Validation Protocol

A validation protocol for IQ/OQ/PQ includes essential components such as the purpose, scope, responsibilities, test procedures, acceptance criteria, and documentation requirements. It also outlines the equipment details, test methods, and data collection processes. Acceptance criteria are predefined to ensure the equipment meets specified standards. The protocol must include detailed step-by-step procedures for each qualification phase. Documentation requirements ensure all activities are recorded, providing traceability. Examples of validation protocols in PDF format often highlight these components, offering a structured approach to qualification. These components ensure the protocol is comprehensive, aligned with regulatory expectations, and repeatable for consistency. Properly defined components are critical for successful equipment validation.

Examples of IQ/OQ/PQ Protocol Templates

IQ/OQ/PQ protocol templates are widely available as PDF documents, offering structured frameworks for equipment validation. These templates typically include sections for installation, operational, and performance qualification, with predefined tables and checklists. They often cover equipment details, test procedures, acceptance criteria, and documentation requirements. Examples include templates from regulatory bodies like the FDA or ISO, which provide standardized formats. Industry-specific templates, such as those for pharmaceutical or medical device industries, are also common. These templates ensure consistency and compliance with regulatory standards. By using these examples, organizations can streamline their validation processes, saving time and reducing errors. Many templates are customizable to fit specific equipment or industry needs.

The Validation Process

The validation process ensures equipment operates consistently, meeting regulatory standards. It involves planning, executing protocols, and documenting results to confirm performance across IQ, OQ, and PQ stages.

Steps Involved in the Validation Process

The validation process begins with planning, where objectives, protocols, and acceptance criteria are defined. Equipment preparation follows, including installation and setup. Testing is conducted according to IQ/OQ/PQ protocols, ensuring compliance with specifications. Data collection and documentation are critical for traceability. Results are reviewed and approved by quality assurance. Deviations are investigated and resolved. Finally, ongoing maintenance ensures sustained performance. This structured approach guarantees regulatory compliance and operational reliability.

Importance of Approved Protocols

Approved protocols are essential for ensuring the validation process meets regulatory requirements and industry standards. They provide a clear framework for IQ/OQ/PQ activities, defining test procedures, acceptance criteria, and documentation standards. Protocols ensure consistency, traceability, and reproducibility of results. They minimize deviations by outlining predefined steps and approval processes. Regulatory agencies require validated processes to be well-documented, and approved protocols serve as evidence of compliance. They also facilitate smooth audits by providing a transparent record of validation activities. Ultimately, approved protocols safeguard product quality and patient safety by ensuring equipment performs as intended under all operational conditions.

Process Study and Design of Experiments

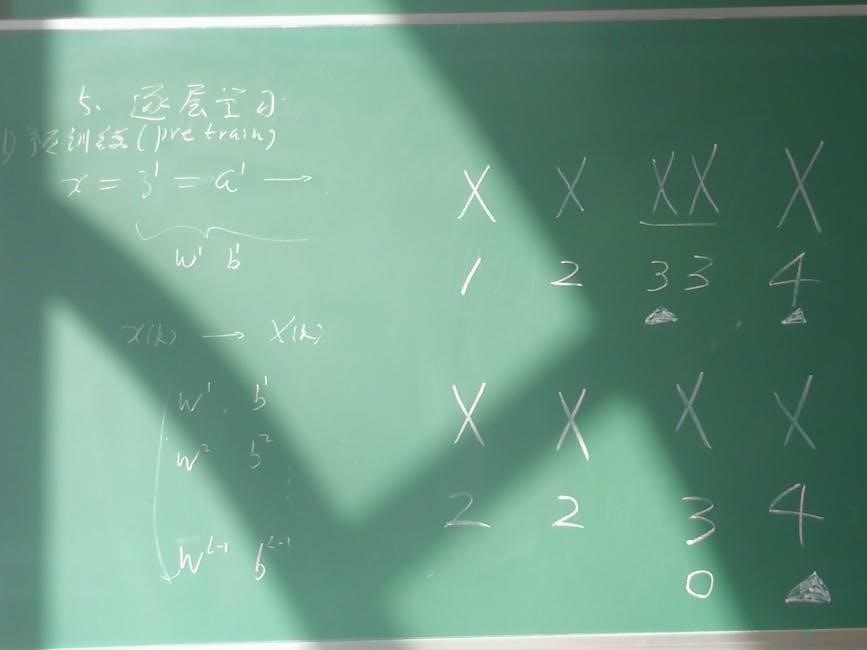

A process study involves systematically analyzing equipment performance to identify critical parameters and operating ranges. Design of Experiments (DoE) is a statistical approach used to evaluate how variables interact and impact outcomes. By applying DoE, validation teams can efficiently test multiple factors simultaneously, reducing the number of experiments needed. This method ensures robust and reproducible results, critical for IQ/OQ/PQ. Process studies also help establish operational limits and verify that the equipment performs consistently under various conditions. The data collected during these studies is essential for generating accurate documentation, ensuring compliance with regulatory requirements and supporting the validation lifecycle.

Examples of IQ/OQ/PQ in Different Industries

IQ/OQ/PQ protocols are essential across industries. Pharmaceuticals ensure drug quality, biotech validates unique processes, and medical devices guarantee patient safety through precise equipment specifications and compliance.

IQ/OQ/PQ in the Pharmaceutical Industry

In the pharmaceutical industry, IQ/OQ/PQ are critical for ensuring drug quality and regulatory compliance. IQ involves verifying equipment installation per design specs and manufacturer recommendations. OQ tests operational limits under simulated conditions, such as temperature and humidity controls in HVAC systems. PQ validates performance over time, ensuring consistent batch production. Examples include qualification of autoclaves, lyophilizers, and chromatography systems. Documentation, like IQ/OQ/PQ reports, must comply with FDA and ICH guidelines. These processes ensure patient safety by verifying equipment reliability and reproducibility in drug manufacturing. Proper execution minimizes deviations and ensures GMP adherence, making IQ/OQ/PQ indispensable in pharmaceutical operations.

IQ/OQ/PQ in Biotechnology

In biotechnology, IQ/OQ/PQ ensure equipment and processes meet stringent quality standards. IQ verifies installation of systems like bioreactors or fermenters, while OQ tests their operational limits under simulated conditions, such as temperature control or agitation speed. PQ validates long-term performance, ensuring consistent production of bioproducts like vaccines or monoclonal antibodies. Examples include qualification of chromatography systems or autoclaves. Documentation, such as validation reports, must align with FDA and ICH guidelines. These processes are critical for maintaining product quality, safety, and regulatory compliance in biotech manufacturing. Proper execution ensures reproducibility and traceability, minimizing risks and deviations in biologic production.

IQ/OQ/PQ in Medical Devices

In the medical device industry, IQ/OQ/PQ are critical for ensuring equipment reliability and compliance with regulatory standards. IQ verifies the correct installation of devices like sterilization equipment or diagnostic tools, while OQ tests their operational performance under specified conditions. PQ validates long-term functionality, ensuring devices consistently meet design specifications. Examples include qualification of autoclaves or infusion pumps. Documentation must align with FDA, ISO, or other relevant standards. These processes are essential for maintaining patient safety and device effectiveness. Proper validation ensures traceability and compliance, minimizing risks and deviations in medical device manufacturing. Detailed records and approved protocols are indispensable for audit and regulatory purposes.

Challenges in IQ/OQ/PQ

IQ/OQ/PQ validation processes face challenges like ensuring compliance, managing deviations, maintaining traceability, and accurate documentation, all while adhering to strict regulatory standards like FDA and ISO guidelines.

Common Challenges in Equipment Validation

Equipment validation, particularly IQ/OQ/PQ, often faces challenges such as ensuring compliance with regulatory standards, managing complex documentation, and addressing unexpected deviations. Maintaining traceability and consistency across processes is critical but can be difficult, especially in large-scale operations. Additionally, the complexity of modern equipment requires highly skilled personnel and precise calibration tools. Resource constraints, such as time and budget limitations, can further complicate validation efforts. Ensuring that all documentation, like IQ/OQ/PQ examples in PDF formats, is accurate and up-to-date adds another layer of complexity. Moreover, staying aligned with evolving regulatory requirements and industry standards demands continuous oversight and adaptation. These challenges highlight the need for robust processes and meticulous planning to ensure successful validation outcomes.

Addressing Deviations in Validation

Deviations in validation processes, such as IQ/OQ/PQ, must be addressed systematically to ensure compliance and reliability. When deviations occur, root cause analysis is essential to identify underlying issues. Corrective actions should be implemented, and their effectiveness verified. Documentation of deviations, including their investigation and resolution, is critical for audit trails. Regulatory requirements must be adhered to, and any impact on product quality or safety assessed. Examples include unexpected test results or equipment malfunctions. A structured approach ensures that deviations are resolved promptly, minimizing risks and maintaining process integrity. Proper documentation, such as IQ/OQ/PQ examples in PDF, helps track and communicate resolution steps effectively.

Ensuring Traceability and GMP Compliance

Traceability and GMP compliance are critical in IQ/OQ/PQ processes to maintain product quality and regulatory adherence. Traceability ensures that all steps in validation can be tracked and verified, from equipment installation to performance testing. GMP compliance involves adhering to standardized procedures, accurate documentation, and consistent operational controls. For example, IQ/OQ/PQ examples in PDF often include detailed logs and records to demonstrate compliance. Regular audits and reviews of validation documentation help identify gaps and ensure alignment with GMP standards. Proper labeling, serialization, and documentation of materials and processes further enhance traceability. By integrating these practices, organizations can ensure seamless compliance and maintain high-quality outcomes throughout the validation lifecycle.

Best Practices for IQ/OQ/PQ

Adhere to standardized procedures, ensure thorough documentation, and involve trained personnel to maintain consistency and compliance. Regularly review and update protocols to align with regulatory requirements and industry standards.

Understanding Controlled and Uncontrolled Inputs

controlled inputs are variables that can be set and monitored during equipment operation, such as temperature or pressure, while uncontrolled inputs, like environmental humidity or operator variability, cannot be directly manipulated. understanding this distinction is critical for validation, as controlled inputs must be precisely managed to ensure consistent results, while uncontrolled inputs should be monitored to assess their potential impact. proper documentation of these inputs is essential for maintaining process control and compliance with regulatory standards. by analyzing examples from iq/oq/pq reports, such as those in pdf formats, one can gain practical insights into how to identify, manage, and document these variables effectively.

Importance of Calibrated Instruments and Documentation

calibrated instruments are essential for ensuring accuracy and reliability in iq/oq/pq processes. proper calibration guarantees that measurements are precise, which is critical for validating equipment performance. documentation of calibration activities provides traceability and demonstrates compliance with regulatory requirements. examples from iq/oq/pq reports, such as those in pdf formats, highlight the necessity of maintaining detailed records; this includes calibration certificates, instrument readings, and verification data. accurate documentation not only supports audit readiness but also ensures that all equipment functions within specified parameters. without calibrated instruments and thorough documentation, the validation process would lack credibility and could lead to non-compliance with industry standards.

Maintaining Full Traceability of Materials and Products

traceability is critical in iq/oq/pq processes to ensure materials and products can be tracked throughout their lifecycle. this involves documenting the origin, processing, and distribution of all components. for example, in iq/oq/pq reports, such as those in pdf formats, traceability ensures that materials used in equipment validation are verified and linked to their sources. proper labeling, batch numbers, and serial codes help maintain this transparency. detailed records of suppliers, manufacturing processes, and testing data are essential. traceability not only supports compliance with regulatory requirements but also enables quick identification and resolution of issues. it ensures accountability and consistency, making it a cornerstone of quality management systems.

Resources for IQ/OQ/PQ

Example Documents and Templates

Access validated IQ/OQ/PQ templates and examples in PDF format from regulatory websites, industry forums, or professional associations like ISPE or PDA for practical guidance.

Regulatory Guidelines and References

Refer to FDA, EMA, or WHO guidelines for detailed instructions on qualification processes, ensuring compliance with global standards and regulatory expectations.

Training and Workshops on IQ/OQ/PQ

Enroll in specialized training programs or workshops offering hands-on experience with IQ/OQ/PQ protocols, including sample PDF documents for real-world application.

Standard templates for IQ/OQ/PQ protocols are widely available to guide the validation process. These documents outline the scope, procedures, and acceptance criteria for each qualification phase. For IQ, common templates include equipment installation checklists, wiring diagrams, and software configuration records. OQ templates often cover operational testing, such as functional checks and performance verification. PQ templates detail testing under various conditions to ensure consistency and reliability. Many organizations provide downloadable PDF examples, such as IQ/OQ/PQ protocol templates, validation master plans, and test scripts. These resources help streamline the process and ensure compliance with regulatory standards. Examples can be found in regulatory guidelines, industry publications, and online repositories like [specific regulatory website] or [industry organization website].

- IQ templates: Installation checklists, wiring verification, and software setup records.

- OQ templates: Functional testing protocols and operational performance evaluation.

- PQ templates: Performance testing scripts and results analysis forms.

These templates are adaptable to specific equipment and industry requirements, ensuring a structured approach to validation.

Regulatory guidelines play a crucial role in ensuring compliance during IQ/OQ/PQ processes. The FDA’s Guidance for Industry: Process Validation provides foundational principles, while the EU’s Annex 15: Qualification and Validation outlines specific requirements for equipment validation. ISO standards, such as ISO 9001 and ISO 13485, also offer frameworks for quality management systems. These documents emphasize the importance of documented evidence, traceability, and adherence to Good Manufacturing Practices (GMP). Additionally, the Pharmaceutical Inspection Convention and Pharmaceutical Inspection Co-operation Scheme (PIC/S) provides detailed guidelines for validation practices. These resources ensure that IQ/OQ/PQ activities align with global regulatory expectations, maintaining product quality and safety.

Examples of references include the FDA’s Validation of Cleaning Processes and the World Health Organization’s (WHO) Validation of Pharmaceutical Processes. These guidelines help organizations implement robust validation strategies, ensuring compliance and consistency across industries.

Training and workshops on IQ/OQ/PQ are essential for ensuring compliance with regulatory standards and enhancing expertise in equipment validation. These programs provide participants with a comprehensive understanding of the principles, processes, and documentation required for successful qualification. Workshops often include hands-on exercises, real-world examples, and interactive discussions to reinforce learning. Topics typically cover the fundamentals of IQ/OQ/PQ, regulatory expectations, and best practices for executing protocols. Many training sessions also address common challenges, such as managing deviations and ensuring traceability. Whether through on-site programs, webinars, or self-paced online courses, these resources empower professionals to confidently implement validation processes and maintain compliance with GMP and industry standards.